Understanding and measuring COPQ (Cost Of Poor Quality) is the first step. But how do you move quality work from insights to actual results? How do you ensure that improvement efforts do not end up as just a report or a few isolated actions? Here, we explain how to truly accelerate your quality work, avoid common pitfalls, and create a culture where quality drives profitability every day.

Understanding and measuring COPQ (Cost Of Poor Quality) is the first step. But how do you move quality work from insights to actual results? How do you ensure that improvement efforts do not end up as just a report or a few isolated actions? Here, we explain how to truly accelerate your quality work, avoid common pitfalls, and create a culture where quality drives profitability every day.

Common Barriers to Effective Quality Management

Many companies know that quality shortcomings are costly, yet improvement efforts still falter. Why? Some typical reasons include:

- Quality is seen as someone else’s responsibility – often “the quality department’s job.”

- Unclear roles and responsibilities – no one knows exactly who is responsible for what in case of deviations.

- Quality data is hidden in Excel files or binders – making it hard to get an overview and act quickly.

- Improvement efforts are reactive – actions are taken only after too much has already been lost.

- Management does not follow up – improvement initiatives lack clear goals and monitoring. All of these barriers can be overcome, but it requires a new approach.

Step-by-Step: How to Make Things Happen

1. Set Goals for Quality Management

Quality goals must be clear, measurable, and relevant to the business. It is not enough to say “higher quality” or “more satisfied customers.” Specific goals can be:

- Reduce the number of customer complaints by 30% over one year.

- Cut the time from detection to resolution of a deviation in half.

- Lower the costs associated with scrap by X amount. Always link the goals to the company’s strategy. This makes it easier to gain management support – and to motivate all employees.

2. Make Quality Everyone’s Responsibility

Shift quality work from being solely the responsibility of the quality department to being an organization-wide effort. Every team and role must take responsibility for their part of the process. One approach is to:

- Implement clear areas of responsibility in process maps – who is responsible for what? What does the process look like?

- Encourage the reporting of deviations and suggestions for improvement from all parts of the organization. This can be easily achieved with digital tools that clearly display responsibility assignments and enable follow-up.

3. Visualize and Monitor – Make Quality Visible

Stop hiding quality data in complicated Excel files. Use KPIs, goals, process maps, and reports that everyone can understand. Here are some tips:

- Update process maps when something changes – so that everyone works from the same picture.

- Create comprehensible reports for the management team – focus on trends and impacts, not just faults. When quality and improvements become visible, it is also easier to engage more people.

4. Move from Firefighting to Prevention

Every day, unnecessary time is spent solving problems that could have been prevented. To reverse this trend:

- Analyze patterns in deviations and complaints – where do the errors recur?

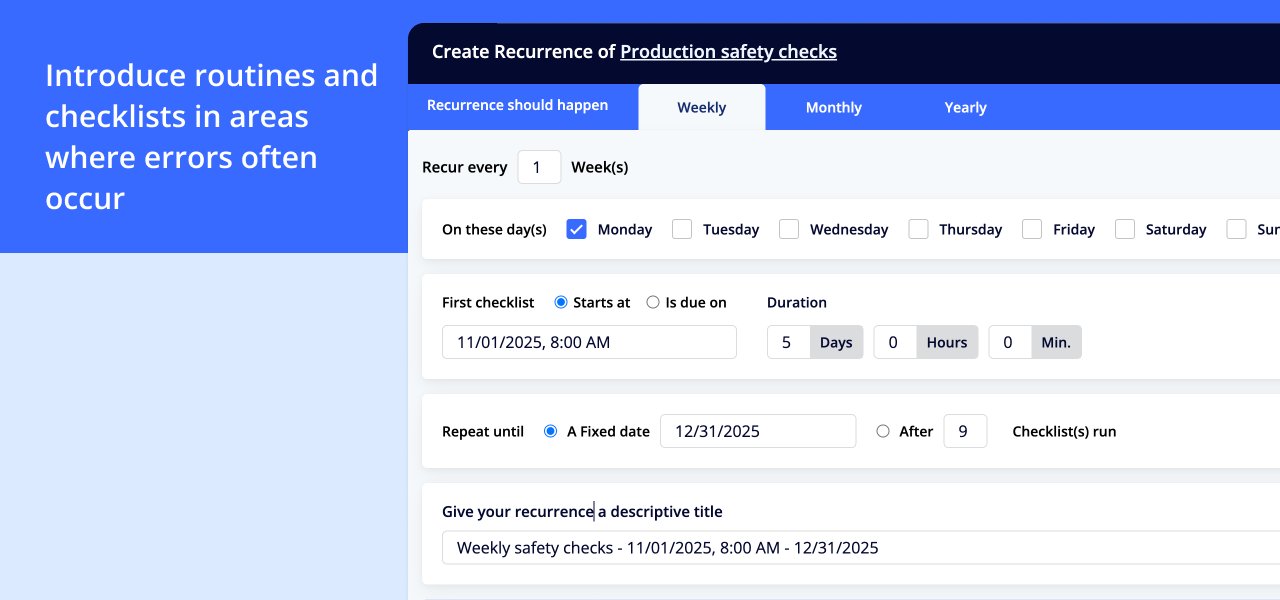

- Introduce routines and checklists in areas where errors often occur – digital tools make this simple.

- Follow up to ensure that implemented measures truly solve the problem – never close a deviation without verification. Here, AmpliFlow can help you quickly identify where the problems are concentrated and where preventive measures have the greatest impact.

5. Make It Easy to Contribute Improvement Suggestions

Many improvements come from those who do the work every day. However, capturing these ideas requires:

- Simple digital reporting of suggestions – preferably via mobile or tablet.

- Quick feedback from managers or responsible persons – show that the ideas are taken seriously.

- Reward or highlight good initiatives – even small improvements count. By digitalizing the process for improvement suggestions, you quickly gather more ideas and can follow up on them systematically.

The Role of Management

It is easy to believe that quality work will “take care of itself” if everyone just reports errors and follows routines. But without firm anchoring from management, little happens in the long run. Management must:

- Set clear expectations and goals for quality management.

- Follow up and discuss quality issues regularly in management meetings.

- Clearly communicate the benefits of improvement efforts – both economically and for the brand.

- Show patience – change takes time, but it is worth the investment. Use management meetings, workshops, and internal newsletters to keep quality issues alive.

How to Avoid Common Mistakes

1. Measuring Too Much or Too Little

Choose a limited number of key indicators that truly matter – and monitor them regularly. Too many indicators mean that none get used effectively. Too few provide insufficient insight.

2. Believing That a Digital System Solves Everything

Digital tools are only aids. It is the people, culture, and leadership that make the difference. Digitalize where it saves time and provides better oversight – but do not forget the importance of dialogue and engagement.

3. Focusing Solely on Internal Errors

The highest costs often come from external errors (complaints, lost customers, damages). Make sure to measure and follow up on both sides.

4. Failing to Follow Up on Implemented Actions

A plan of action is only valuable if someone is responsible for its implementation – and if its effects are measured. Always provide feedback to the person who reported an error or suggested an improvement.

Sustaining Improvement Efforts – Year After Year

It is easy to start enthusiastically – but harder to maintain momentum over time. Here are some tips:

- Schedule regular quality meetings – both at team and management levels.

- Rotate responsibility for certain quality tasks – so that more people learn and get engaged.

- Celebrate successes visibly – highlight good examples in the company’s internal channels.

- Review goals and routines annually – adjust as the business evolves.

The Right Tools Make a Difference – But Only If They Are Used

Digital management systems like AmpliFlow make it easier to collect, analyze, and act on quality data. But it is only a tool. To succeed, you must:

- Train all users – and make the system a natural part of everyday work.

- Adapt your management system to your needs – not to bureaucracy.

- Follow up to ensure that processes and routines are genuinely being followed.

Summary – From Theory to Results

Quality work is not just a side project, but a driver for increased profitability and more satisfied customers. By:

- Setting clear goals

- Engaging all employees

- Measuring and monitoring the right factors

- Implementing digital tools that simplify and make improvements visible

- Having management as an active driver …you can move from ambitious plans to real results.

When quality work is ingrained in your organization, it naturally leads to continuously eliminating COPQ – freeing up time, money, and energy for what truly creates value for customers and the business.

Begin simply. Make it visible. Keep at it. The results will follow.

Would you like to learn more about how AmpliFlow can help your company reduce COPQ and boost quality efforts? Contact us for a demo or book a meeting!